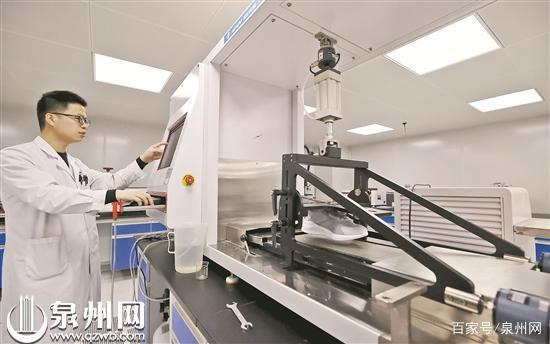

In the testing center of China Leather and Footwear Industry Research Institute (Jinjiang) Co., Ltd., technicians use high-end instruments to test the anti-slip properties of shoe soles.

Guided by the spirit of the city's 13th Party Congress, Quanzhou is building a "strong city with wisdom". A few days ago, Quanzhou City held a mobilization on-site meeting and a video deployment meeting for the special action of green digital technological transformation, grasping innovation and promoting application. When interviewing enterprises, the reporter felt that from the aspects of intelligent transformation, green transformation, digital transformation, technological system innovation, etc. The construction boom of "intelligently building a strong city" is surging in Quanzhou.

In the smart workshop of Fujian Huaang Sporting Goods Co., Ltd., the shoe molding processes such as heating, gluing, and lamination, which depended on manual labor, have been replaced by intelligent assembly lines. Double shoes." Talking about the benefits of intelligent production to the enterprise, Chairman Huang Jinhuang said, "Intelligent transformation has reduced the labor of our molding line by 75%, but it has increased the company's annual production capacity by 25%. The unit price per customer has doubled, and this year, Versace, an international luxury brand, has also come to us to cooperate.” After tasting the sweetness, Hua Ang Sports is building a digital R&D center, “Next year, we will be able to enter digital operations and realize the full production process. Visualize."

Walking into the testing center of China Leather and Footwear Industry Research Institute (Jinjiang) Co., Ltd., more than 300 various testing instruments are distributed in various laboratories. They can test almost all the properties of a pair of shoes, such as wear resistance, Moisture and heat resistance, water and alkali resistance, slip resistance, skin touch, etc. The reporter saw that in order to test the folding resistance, there is a piece of equipment that is folding and pressing a row of shoe samples at high speed. "Now Quanzhou's shoe and apparel companies no longer need to go to Beijing to seek technical services." The relevant person in charge of the research institute introduced that the testing center has passed CNAS and CMA certification, and has 244 parameters of 96 products in 7 categories of textile shoes and clothing. The third-party testing capability has provided technical services for more than 520 enterprises last year alone.

When I came to the exhibition hall of Xintai (Fujian) Technology Co., Ltd., a pair of digitally applied sneakers was amazing. By implanting an automatic control airbag, the shoes can be used to control the tightness of the wearing with the voice of the mobile phone APP. Not only the product research and development side, but also the digital transformation of Xintai on the production side. The staff introduced that through the industrial Internet of Things platform, Xintai can control every equipment and process in the workshop, and can also monitor the energy consumption of water, electricity, coal, gas, etc. in real time, and use big data for production efficiency analysis. At present, riding the east wind of the digital economy, Xintai is accelerating the construction of the 5G intelligent manufacturing industrial park in Shishi.

In the red demonstration production line of Fujian Panpan Beverage Co., Ltd., thousands of square meters of sterile workshop, at a glance, water treatment, ingredients, cap making, bottle making, bottle blowing, filling, sleeve labeling, wrapping and coding A series of processes such as stacking are completed in one go. According to the relevant person in charge, this Krones aseptic filling machine is from Germany. It is the world's most advanced aseptic automatic filling machine. It has 100 attention heads and 30 capping heads. Disinfection, and the production capacity is as high as 43,200 bottles per hour. "We have a national CNAS-approved inspection and testing center, and a factory environment with three-level air filtration, constant temperature and humidity, and 100,000-level purification workshop technology."

□Reporter Wang Shufan/Text Chen Xiaoyang/Photo

[Source: Quanzhou Net]

|